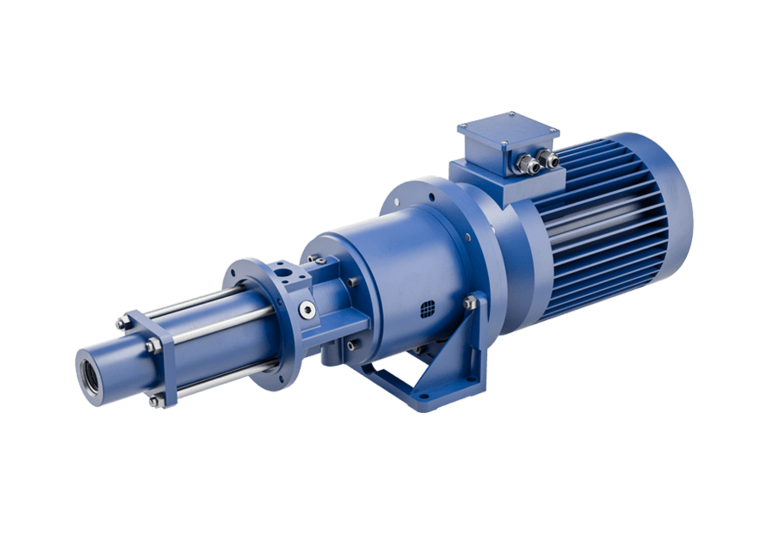

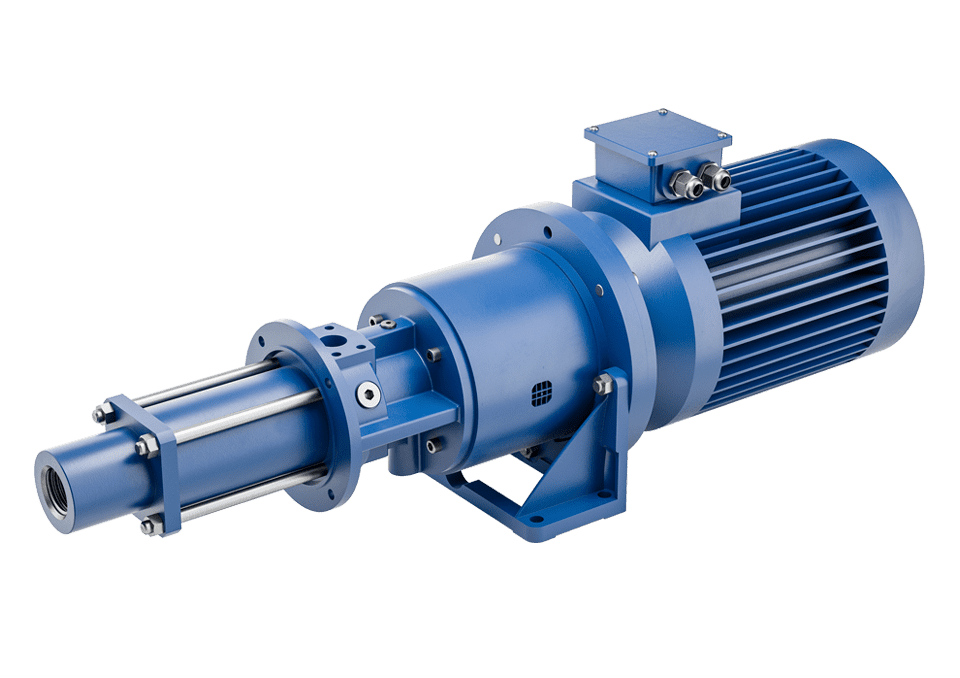

Operation, materials, components.

- Delivery rate: 15 to 290 l/min.

- Max. differential pressure: 120 bar.

- Viscosity: > 1 mm²/s.

- Max. temperature: To 180 °C, magnetic coupling to 300 °C.

- Installation: Wet or dry.

- Spindle housing: Nodular cast iron EN-GJS-400, polymer-coated or other material options.

- Screws: Steel, nitrided.

Optimum pump for special requirements.

Pumped fluids such as cooling lubricants are difficult liquids. They contain abrasive dirt, mostly metal residues, and must be pumped at high pressure. In addition, they have a very low viscosity of only about 1 mm²/s.

In the KRAL screw pump of the W series, the screw material and the casing coating have been designed for improved sliding properties in such a way that low viscosity fluids can be pumped with high efficiency.

The running casing is coated with a resistant polymer that can absorb particles. The balancing cylinder of the screw pump has orifice insertions to reduce the leakage rate, therefore efficiency remains high.

KRAL pumps for special requirements.

Compared with other screw pump principles, KRAL screw pumps offer a high flow rate while requiring little space. KRAL pumps deliver continuously and with low pulsation, which protects the pumped media even under difficult conditions.

Installation options.

The KRAL W series screw pump can be designed for dry or wet-well installation. For a vertical wet-well installation, a mounting plate is provided.

Your advantages.

- Resistant, polymer-coated running casing absorbs particles.

- High pressure up to maximum 120 bar at low viscosity.

-

Conveying abrasive liquids.

-

Gentle conveying of the liquid.

- Low pulsation, quiet.

- Multiple installation variations available.

- For many different applications – as you can see in our product catalog or on our website pump overview.

| Technical data | 15-26 | 32-54 | 55-85 | 105-118 | |

|---|---|---|---|---|---|

| Qth (1450 min-1, 0 bar) | l/min | 15-26 | 32-54 | 55-85 | 105-118 |

| Max. pressure at pressure flange | bar | 120 | 120 | 120 | 120 |

| Temperature max. pumped liquid | °C | ||||

| with radial shaft seal NBR | 90 | 90 | 90 | 90 | |

| with radial shaft seal FKM | 150 | 150 | 150 | 150 | |

| with mechanical seal standard | 150 | 150 | 150 | 150 | |

| with mechanical seal hard material | 180 | 180 | 180 | 180 | |

| with magnetic coupling | 300 | 300 | 300 | 300 | |

| Viscosity | mm²/s | ||||

| min. | 1.0 | 1.0 | 1.0 | 1.0 | |

| max. | 100,000 | 100,000 | 100,000 | 100,000 | |

| Max. pressure at suction flange | bar | ||||

| with radial sealing ring | 6 | 6 | 6 | 6 | |

| with mechanical seal standard | 6 | 6 | 6 | 6 | |

| with mechanical seal hard material | 6 | 6 | 6 | 6 | |

| with magnetic coupling | 6 | 6 | 6 | 6 | |