KRAL Screw Pumps for Tank Applications.

Loading and unloading pumps for fuel oil.

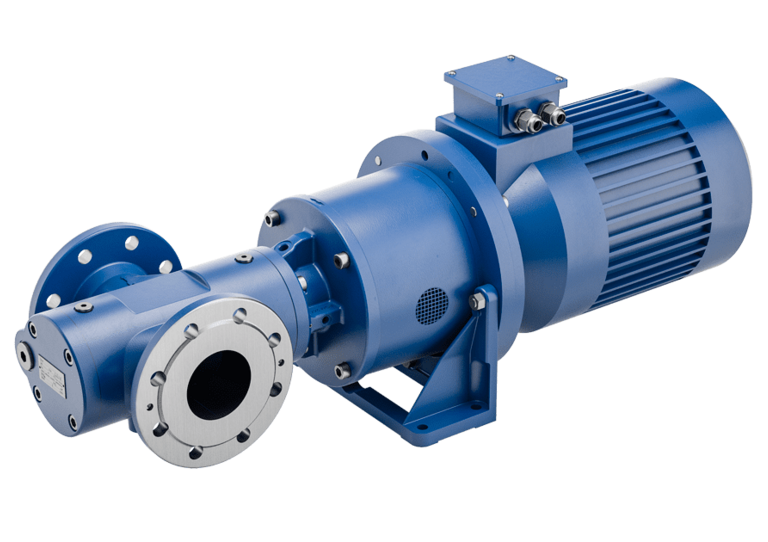

KRAL screw pumps from all series are suitable for unloading heating oil and diesel from tankers, railway wagons, and ships. However, we particularly recommend the KRAL two screw pumps from the Z series. Their advantages include: High dry-running capability, excellent suction performance, low-pulsation delivery, and maximum connection flexibility thanks to unlimited variable connection arrangements. In contrast to other solutions, the delivery direction can also be easily changed for a short time.

Delivery rate: 5 to 2,900 l/min.

Max. differential pressure: 16 bar.

Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

Housing: Nodular cast iron EN-GJS-400.

Screws: Steel, nitrided.

Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA.

ATEX: II 2 GD b/c group II,

category 2.

Heating: Electrical, media or steam.

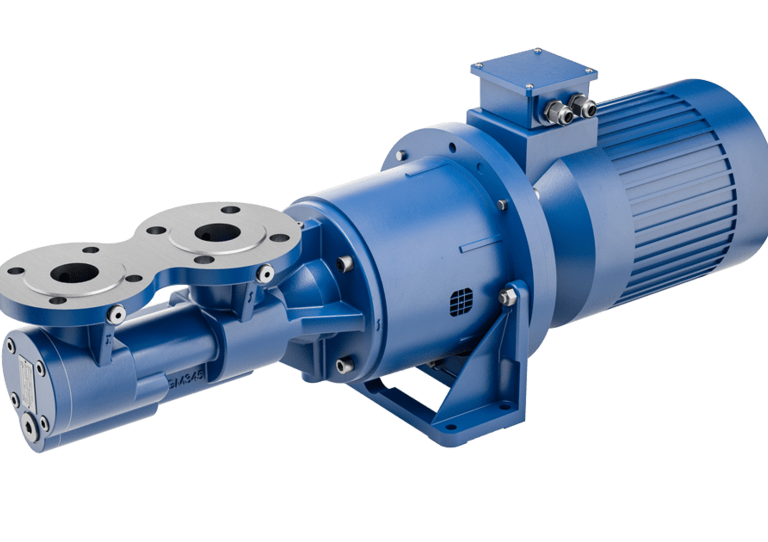

Delivery rate: 5 to 200 l/min.

Max. pressure: 63 bar.

Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

Housing: Nodular cast iron EN-GJS-400.

Screws: Steel, nitrided.

Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

ATEX: II 2 GD b/c group II, category 2

Heating: Electrical, media or steam.

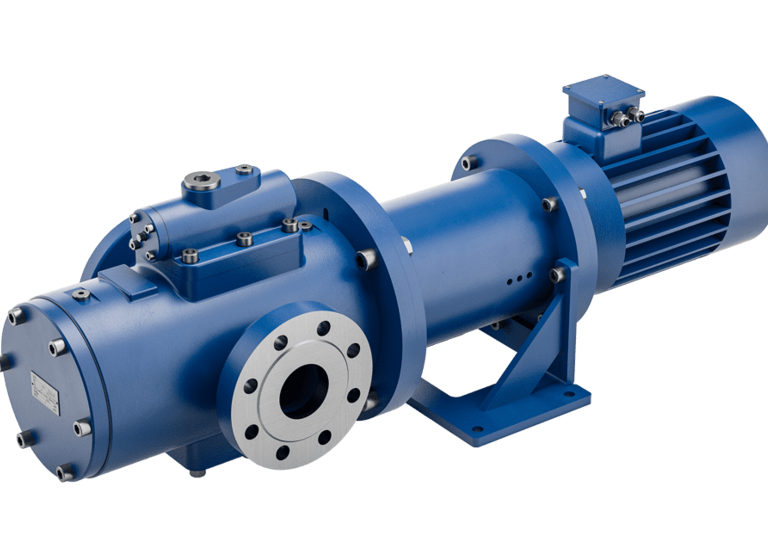

Delivery rate: CK: 5 to 1,750 l/min / CL & CG: 5 to 3,550 l/min.

Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

Pressure range: 70 bar; 100 bar.

Housing: Nodular cast iron, steel and aluminium.

Screws: Steel, nitrided.

Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

ATEX: II 2 GD b/c group II,

category 2.

Heating: Electrical, media or steam.

API: Manufactured to conform

with API.

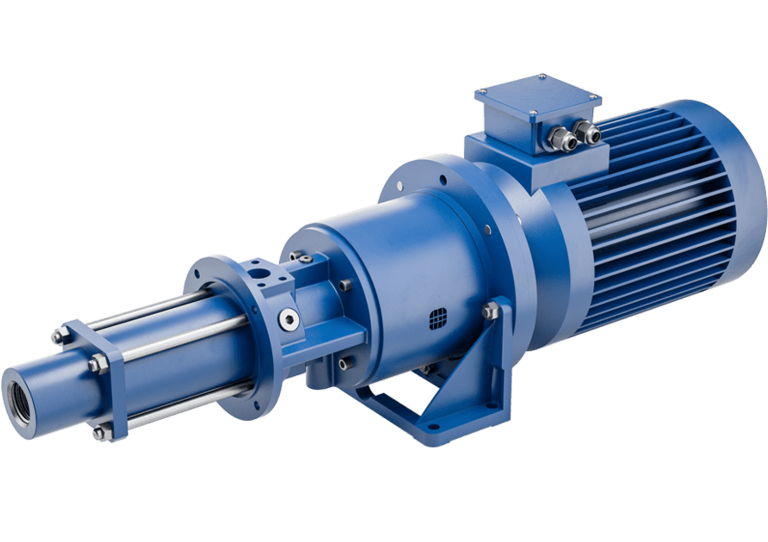

Delivery rate: 15 to 290 l/min.

Max. differential pressure: 120 bar.

Viscosity: > 1 mm2/sec.

Max. temperature: to 180 °C, magnetic coupling to 300 °C.

Installation: Wet or dry.

Spindle housing: Nodular cast iron EN-GJS-400, polymer-coated or other material options.

Screws: Steel, nitrided.