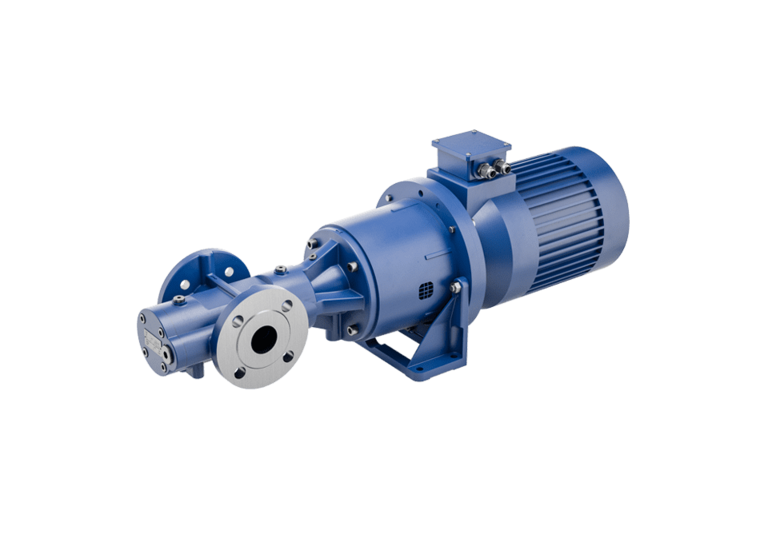

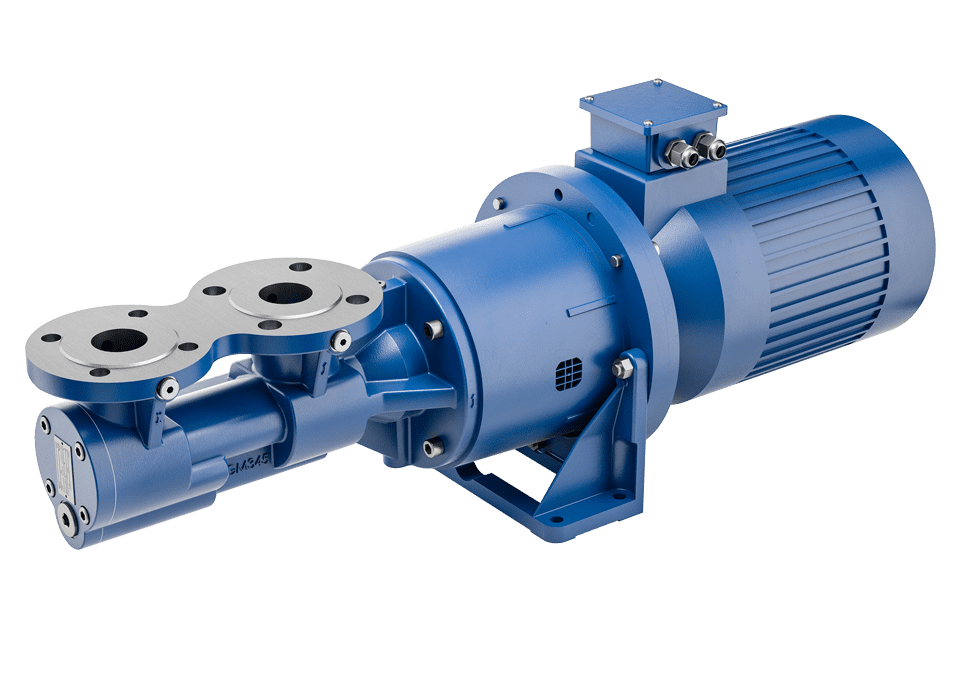

KRAL L Series Screw Pumps.

Compact, low-wear pump up to 63 bar.

Robust, versatile and easy to maintain.

Versatile, compact and efficient like the K series, but for higher operating pressures up to 63 bar: the KRAL L series screw pump is the preferred choice for medium-pressure applications in the marine sector as well as numerous applications in the oil and gas, power generation, mechanical engineering and chemical industries. It has a spheroidal cast iron housing and is approved for use on board ships.

Operation, materials, components.

- Delivery rate: 5 to 160 l/min.

- Max. pressure: 63 bar.

- Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

- Viscosity: 7,000 mm²/s.

- Housing: Nodular cast iron EN-GJS-400.

- Screws: Steel, nitrided.

- Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

- ATEX: II 2 GD b/c group II, category 2.

- Heating: Electrical, media or steam.

L series screw pumps in the KRAL serial program.

Other pump technologies have the disadvantage that they can only be operated at low speed due to the high risk of damage. KRAL screw pumps, on the other hand, are gentle on the medium, even at high speeds. This guarantees high operating efficiency and an excellent price/performance ratio.

All screw pumps of the KRAL L series also offer reliable startup, minimal wear, and ease of maintenance, which simplify operation. Available with magnetic coupling or external ball bearing (maintenance-free).

Easy servicing.

The main spindle of the L series can be disassambled together with the seal casing, as all the rotating parts are pre-assembled in the removable end cover. This makes the screw pump particularly easy to assemble, dismantle and maintain.

KRAL L series use lifetime-lubricated, external ball bearings. FKM sealing discs with high temperature stability prevent wash out. This increases the life of the bearing and reduces maintenance costs.

The innovative one-piece casing design guarantees that pressure-side leakages are a thing of the past.

Your advantages.

- High efficiency.

- Gentle on the media even at high speeds.

- Low wear, easy maintenance.

- Approved on board ships.

- Low maintenance costs.

- Top and inline flange for every size.

- Max. pressure: 63 bar.

- Temperature with magnetic coupling up to 300 °C.

- Viscosity of 7,000 mm²/s.

- Used in KRAL single pump stations and KRAL dual stations.

| Technical data | 5-10 | 15-26 | 32-54 | 55-85 | |

|---|---|---|---|---|---|

| Qth (1450 min-1, 0 bar) | l/min | 5-10 | 15-26 | 32-54 | 55-85 |

| Max. pressure at pressure flange | bar | 63 | 63 | 63 | 63 |

| Temperature max. pumped liquid | °C | ||||

| with radial shaft seal NBR | 90 | 90 | 90 | 90 | |

| with radial shaft seal FKM | 150 | 150 | 150 | 150 | |

| with mechanical seal standard | 150 | 150 | 150 | 150 | |

| with mechanical seal hard material | 180 | 180 | 180 | 180 | |

| with magnetic coupling | 300 | 300 | 300 | 300 | |

| Viscosity | mm²/s | ||||

| min. | 1.1 | 1.1 | 1.1 | 1.1 | |

| max. | 7,000 | 7,000 | 7,000 | 7,000 | |

| Max. pressure at suction flange | bar | ||||

| with radial sealing ring | 1.5 | 1.5 | 1.5 | 1.5 | |

| with mechanical seal standard | 6 | 6 | 6 | 6 | |

| with mechanical seal hard material | 10 | 10 | 10 | 10 | |

| with balanced mechanical seal model LFI/LFT/LFW/LVI/LVT model LFM | 20 6 | 20 6 | 20 6 | 20 6 | |

| with magnetic coupling model LFI/LFT/LFW/LVI/LVT model LFM | 20 6 | 20 6 | 20 6 | 20 6 | |