KRAL Screw Pumps for Hydraulic Applications.

Hydraulic pumps for thermal power plants.

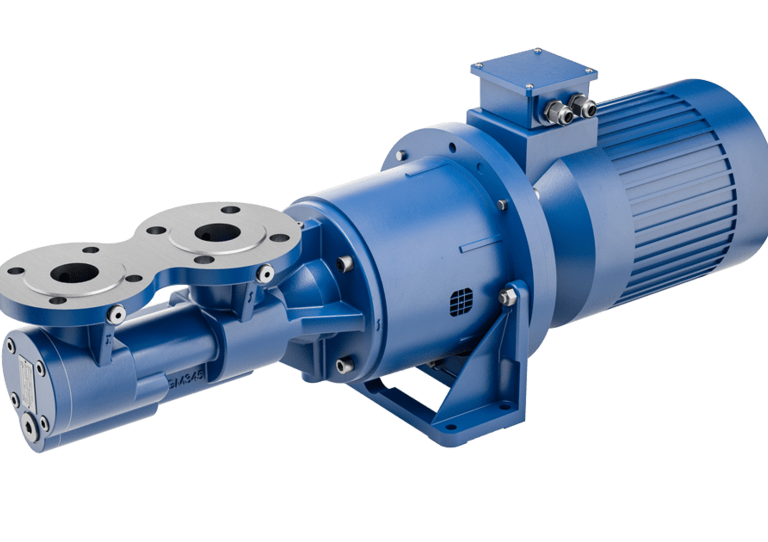

As a hydraulic pump for medium pressures, the L series is also a robust, low-wear, and cost-effective solution. For particularly high differential pressures, we recommend the W series.

Hydraulic pumps for hydropower plants.

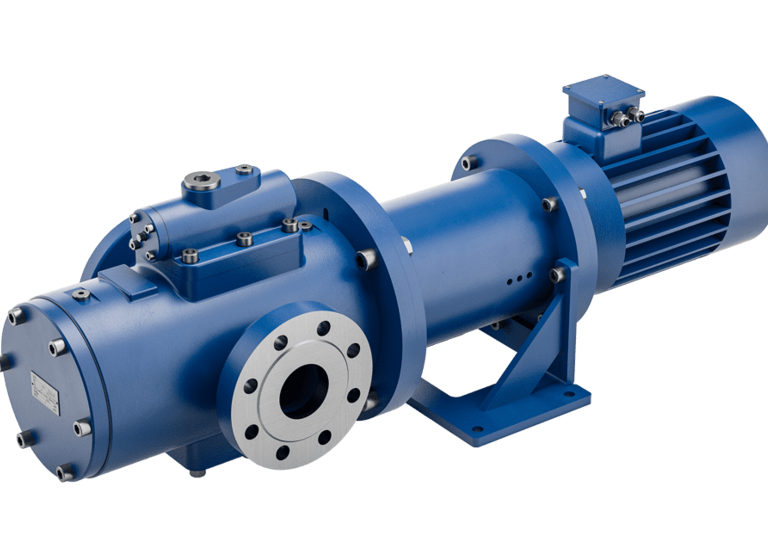

The KRAL three screw pumps from the C series (as high-pressure pumps up to 100 bar) or the W series (for particularly high differential pressures) are particularly suitable as pump systems for supplying the hydraulics that control water turbine guide wheels under a wide variety of flow conditions.

Jacking pumps.

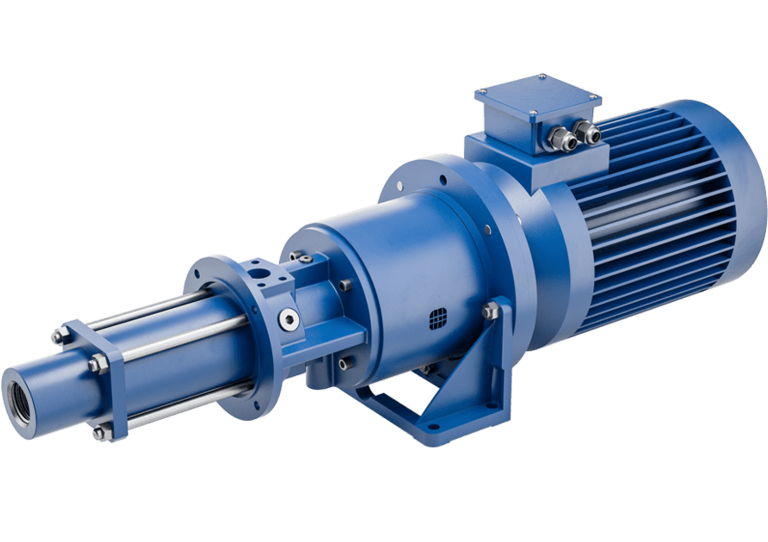

KRAL W series three screw pumps are also a reliable solution for lifting the rotor and generator shafts when starting a turbine. They allow a fast pressure increase up to 120 bar. The pumps can be supplied in submerged in-tank or outside tank dry mount as required.

Adjustment pumps for wind turbines.

To increase generator efficiency in various weather scenarios, depending on the system requirements, we recommend the KRAL L or C series three screw pumps for hydraulic adjustment of wind turbine rotors.

- Rudder adjustment.

- Propeller blade adjustment.

- Providing service for hydraulic drives.

- Raising turbine bearings.

- Hydraulic pump for plant facilities.

Delivery rate: 5 to 200 l/min.

Max. pressure: 63 bar.

Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

Housing: Nodular cast iron EN-GJS-400.

Screws: Steel, nitrided.

Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

ATEX: II 2 GD b/c group II, category 2

Heating: Electrical, media or steam.

Delivery rate: CK: 5 to 1,750 l/min / CL & CG: 5 to 3,550 l/min.

Temperature range: -20 °C to 180 °C, magnetic coupling to 300 °C.

Pressure range: 70 bar; 100 bar.

Housing: Nodular cast iron, steel and aluminium.

Screws: Steel, nitrided.

Approvals: ABS, BV, CCS, DNV, GL, LRS, MRS, NK, RINA, KR.

ATEX: II 2 GD b/c group II,

category 2.

Heating: Electrical, media or steam.

API: Manufactured to conform

with API.

Delivery rate: 15 to 290 l/min.

Max. differential pressure: 120 bar.

Viscosity: > 1 mm2/sec.

Max. temperature: to 180 °C, magnetic coupling to 300 °C.

Installation: Wet or dry.

Spindle housing: Nodular cast iron EN-GJS-400, polymer-coated or other material options.

Screws: Steel, nitrided.