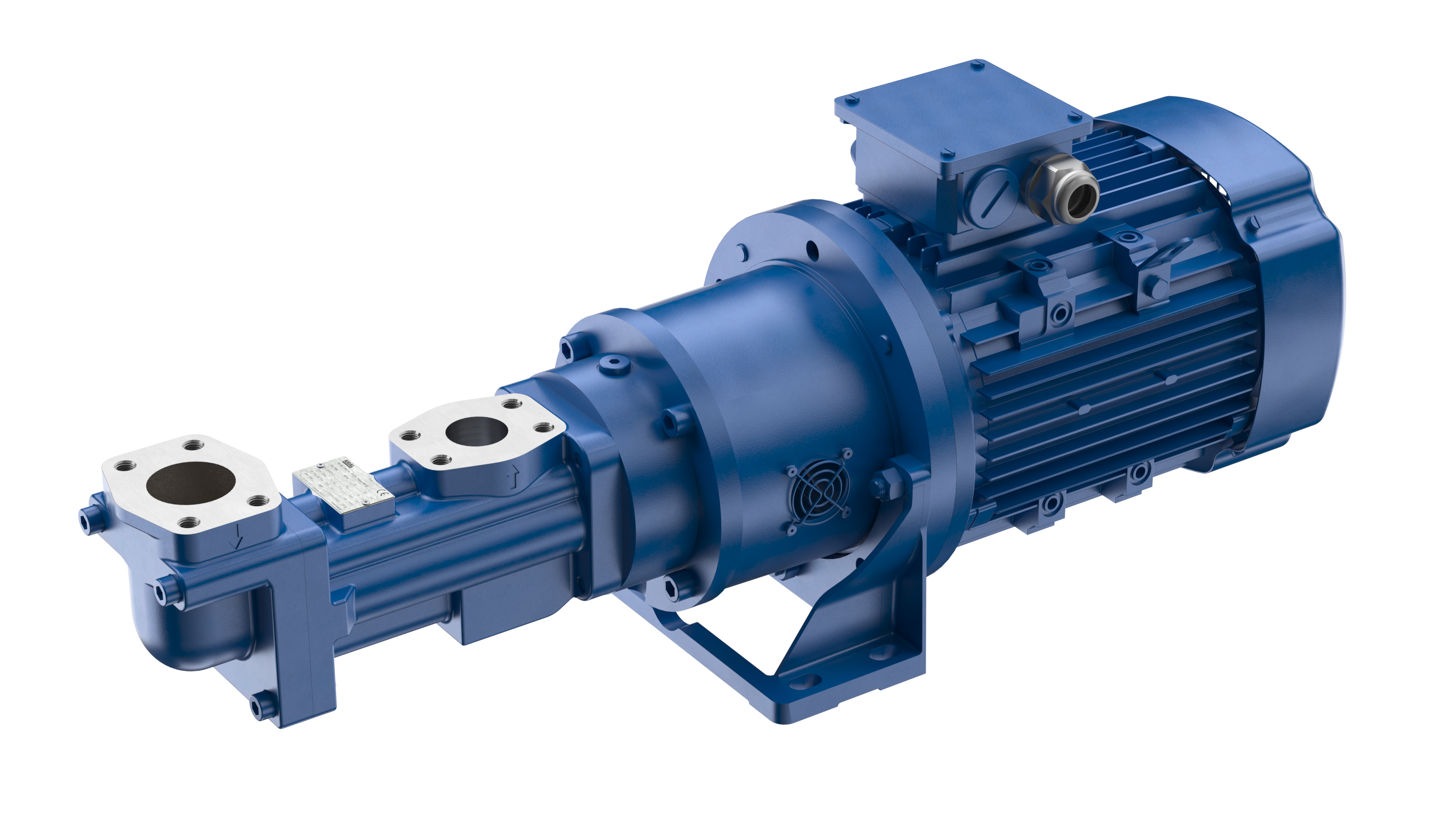

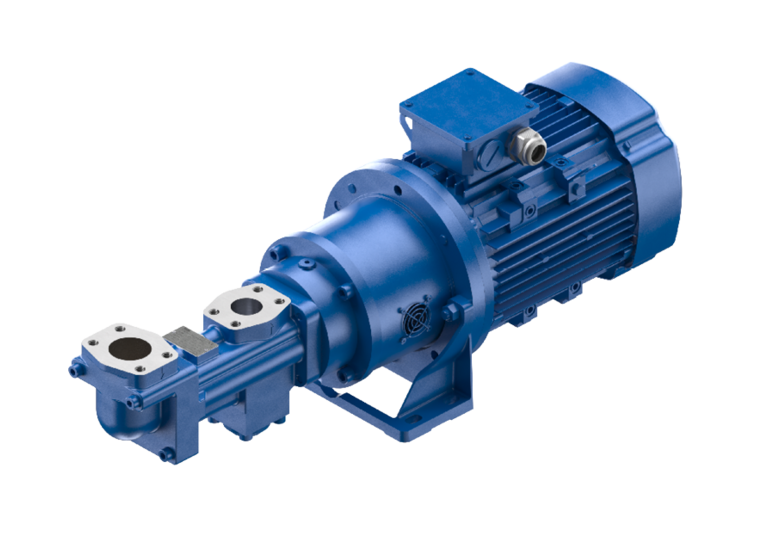

KRAL G Series Screw Pumps.

Compact lubricating oil pump in modular design.

Everything that moves, whether sliding or rolling, must be lubricated. Energy and cost Efficiency are paramount for operators of rotating machinery, such as compressors, gearboxes and turbines.

The pump that adapts to your needs. The KRAL G series screw pump impresses with a multitude of advantages.

Operation, materials, components.

- Delivery rates: 5 to 660 l/min.

- Max. Differential pressure: 25 bar.

- Temperature range: -10 °C to 120 °C.

- Magnetic coupling to 300 °C.

- Viscosity: 10 to 500 mm²/s.

- Coldstart to 1200 mm²/s.

- Housing: Nodular cast iron EN-GJS-400, steel.

- Spindles: Steel, nitrided.

- Certificates: ABS, BV, DNV, LRS.

- API: Conformance with API 676.

- Options for ATEX :

- EX II -/3 G Ex h IIC T4... T2-/Gc X., with mechanical seal.

- EX II -/2 G Ex h IIC T4 ... T2-/Gb X., with magnetic coupling.

Modular structure.

The modular design of the G series allows for easy customization and configuration according to the specific requirements of the customer. This flexibility makes the pump extremely versatile and adaptable, making it an ideal choice for a wide range of applications. The pump housing, suction, and flange covers can each be rotated in 90° increments. Suction cover with radial and axial connection.

Standardized process connections.

The use of standardized process connections not only simplifies integration into existing systems but also ensures smooth compatibility with various industry standards. As a result, the pump is not only powerful but can also be seamlessly integrated into existing processes.

Compact design.

TThe compact design of the G series allows for space-saving installation without compromising performance. This is especially important in environments where available space is limited and enables efficient use of the existing area. The pump can be installed either horizontally or vertically and is available in both submersible and dry-mounted versions.

Short delivery times and a good price-performance ratio.

The attractive price allows companies to benefit from the latest pump technology without straining their budget. As a result, the pump offers excellent value for money. Our short delivery times ensure rapid availability of the pump in today’s fast-paced industry, where time is often a critical factor.

| Technical data | 15-20 | 32-42 | 55-85 | 105-118 | 160-210 | 235-275 | |

|---|---|---|---|---|---|---|---|

| Qth (1450 min-1, 0 bar) | l/min | 15-20 | 32-42 | 55-85 | 105-118 | 160-210 | 235-275 |

| Max. pressure at pressure flange | bar | 25 | 25 | 25 | 25 | 25 | 25 |

| Temperature | °C | ||||||

| with mechanical seal | 120 | 120 | 120 | 120 | 120 | 120 | |

| with magnetic coupling | 300 | 300 | 300 | 300 | 300 | 300 | |

| Viscosity | mm²/s | ||||||

| min. | 10 | 10 | 10 | 10 | 10 | 10 | |

| max. | 500 | 500 | 500 | 500 | 500 | 500 | |

| Coldstart | 1.200 | 1.200 | 1.200 | 1.200 | 1.200 | 1.200 | |

| Max. pressure at suction flange | bar | ||||||

| with mechanical seal | 6 | 6 | 6 | 6 | 6 | 6 | |

| with magnetic coupling | 16 | 16 | 16 | 16 | 16 | 16 | |

For gearbox attachment with or without clutch. With axial inlet.

Mounting on the pump bracket with foot. With radial inlet. With relief valve.

Space-saving due to pressure connection above the mounting plate. Suitable for low tank heights.

Classic tank installation. With mounting plate.